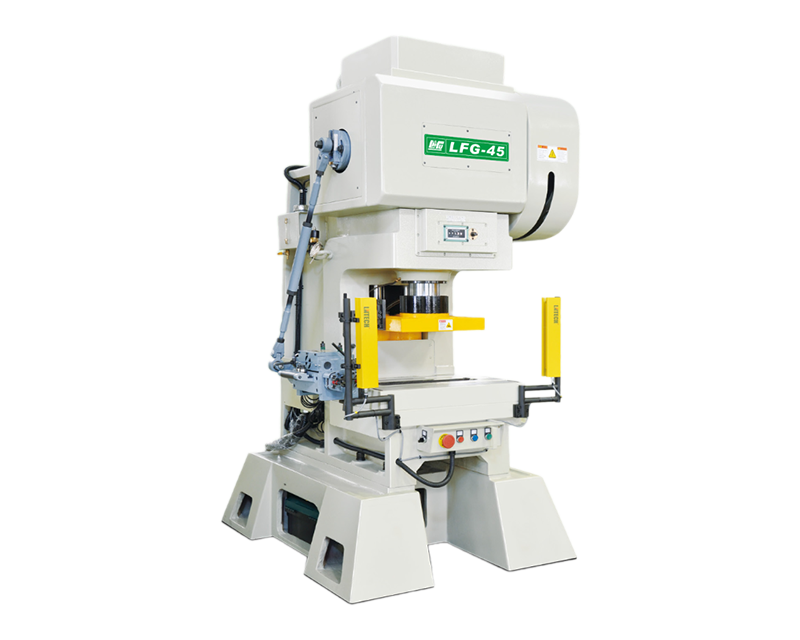

H-frame high speed press

Product Description

LFL Series High-Speed Press Machines (30–65 Tons)

The LFL Series High-Speed Press Machines are designed for manufacturers requiring a compact, high-performance solution for precision metal stamping. With available capacities of 30, 45, and 65 tons, these machines are ideal for progressive die stamping, electronic parts production, automotive components, terminal forming, and small hardware applications.

Key Features

-

Flexible Stroke Configuration

Each model supports multiple stroke lengths (20 to 50 mm), making it suitable for a wide variety of die designs and production processes. -

High-Speed Stamping Capability

Up to 1000 strokes per minute (SPM) on the LFL-30, with efficient stroke-speed combinations across all models. -

Adjustable Die Height

Die height ranges from 185 mm to 325 mm, depending on model and stroke length, ensuring compatibility with different die setups. -

Sturdy and Compact Construction

Bolster areas up to 950×700 mm and slide adjustment up to 50 mm enable smooth operation with excellent stability and part repeatability. -

Reliable Drive & Control Systems

Equipped with inverter-controlled motor, pneumatic clutch and brake, and standard auto top stop for safe and efficient operation. -

Advanced Lubrication & Vibration System

Integrated oil lubricating system with oil cooler and optional air cushion or spring-type vibration system for extended machine life and smoother performance.

Typical Applications

-

Electronic connectors, terminals, and precision components

-

Stamping of metal shells, button parts, and fasteners

-

Progressive die applications with high repeat accuracy

-

Small automotive components and sensor casings

-

General hardware and thin-sheet forming

Customization Options

-

Stroke length adjustment by order

-

Servo feeder and uncoiler integration

-

Optional CE or UL certified electrical cabinet

-

Die protection, air blow, and light curtain system

-

Touchscreen HMI and production monitoring

OEM and customized configurations are available to meet specific manufacturing requirements. Technical data sheets and quotations are available upon request.

| Model | LFL-30 | LFL-45 | LFL-65 |

|---|---|---|---|

| Capacity (Ton) | 30 | 45 | 65 |

| Stroke Length (mm) | 20 / 25 / 40 | 20 / 25 / 30 / 40 | 20 / 25 / 30 / 40 / 50 |

| Stroke Per Minute (SPM) | 200–1000 / 200–900 / 200–600 | 200–900 / 200–800 / 200–700 / 200–600 | 200–800 / 200–500 / 200–400 |

| Die Height (mm) | 195–235 / 192–230 / 185–225 | 230–280 / 227–277 / 225–275 / 220–270 | 275–325 / 270–320 / 265–315 / 260–310 |

| Slide Area (mm) | 620×340 | 750×380 | 900×450 |

| Bolster Area (mm) | 650×470×110 | 800×550×120 | 950×700×135 |

| Slide Adjustment (mm) | 40 | 50 | 50 |

| Bed Opening (mm) | 500×100 | 650×580×20 | 650×125 |

| Motor Power (kW) | 7.5 | 11 | 18.5 |

| Lubrication | Oil lubricating system with oil cooling machine | Oil lubricating system with oil cooling machine | Oil lubricating system with oil cooling machine |

| Speed Control | Inverter | Inverter | Inverter |

| Clutch & Brake | Pneumatic friction | Pneumatic friction | Pneumatic friction |

| Auto Top Stop | Standard | Standard | Standard |

| Vibration System | Air cushion type & spring type are available | Air cushion type & spring type are available | Air cushion type & spring type are available |

Be the first to review “H-frame high speed press”

Like what you see?

Check our case studies.

Reviews

There are no reviews yet.