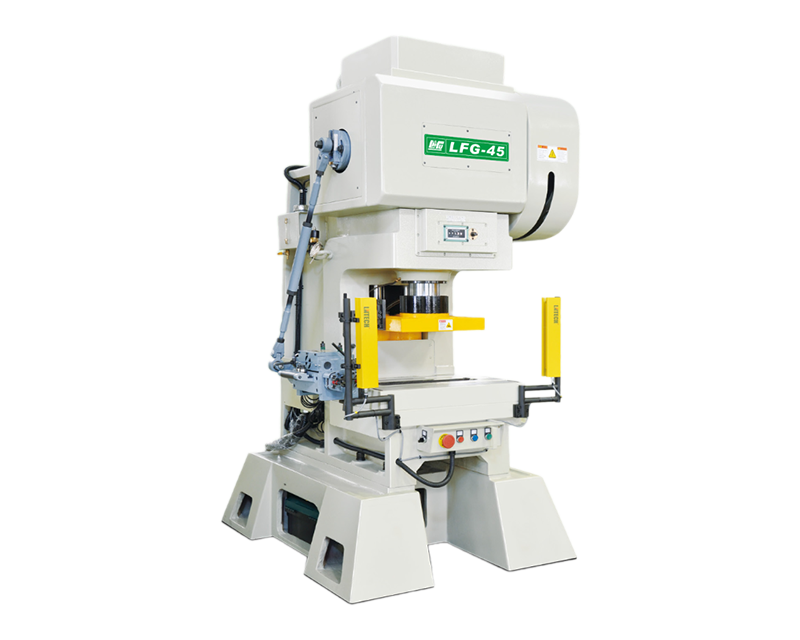

Three-circular guide pillar high speed punch

Product Description

LFG Series High-Speed Precision Press Machines (30–80 Tons)

The LFG Series High-Speed Precision Press is designed for industries that demand high-accuracy, high-frequency stamping performance. Covering capacities from 30 to 80 tons, the LFG Series is ideal for producing small to medium-sized components in electronics, hardware, automotive parts, connectors, and terminal stamping applications.

Key Features

-

Multiple Stroke Options

Each tonnage model supports three stroke lengths (20 / 30 / 40 mm), providing flexibility for a variety of dies and material thicknesses. -

High-Speed Capability

The LFG-30 reaches up to 900 SPM (strokes per minute), while higher tonnage models maintain speeds up to 600 SPM, making it suitable for continuous, high-output operations. -

Stable and Precise Die Performance

With shut height settings ranging from 210 mm to 360 mm and adjustable slide lengths up to 50 mm, the press ensures accuracy even under high-speed conditions. -

Heavy-Duty Bolster and Bed Design

Bolster sizes up to 1000×590 mm and bed openings engineered for efficient scrap discharge, die accessibility, and automation system compatibility. -

Compact and Efficient Structure

Space-saving machine footprints with motor powers from 3.7 kW to 15 kW help reduce energy consumption and fit seamlessly into production lines.

Application Scope

-

Precision stamping for terminals, lead frames, and electronic connectors

-

Progressive die punching for hardware and small automotive parts

-

Button and fastener forming in consumer electronics and fashion accessories

-

Small motor and battery case component production

-

Medium-speed high-volume production with multi-stage tooling

| Model | LFG-30 | LFG-45 | LFG-65 | LFG-80 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | A | B | C | A | B | C | A | B | |

| Capacity (Ton) | 30 | 30 | 30 | 45 | 45 | 45 | 65 | 65 | 65 | 80 | 80 |

| Stroke (mm) | 20 | 30 | 40 | 20 | 30 | 40 | 20 | 30 | 40 | 30 | 50 |

| Stroke Per Minute | 200–700 | 200–500 | 200–400 | 200–700 | 200–500 | 200–400 | 200–600 | 200–500 | 200–400 | 200–600 | 200–400 |

| Stroke Per Minute | 200–900 | 200–600 | 200–500 | 200–900 | 200–600 | 200–500 | 200–700 | 200–500 | 200–400 | 200–600 | 200–500 |

| Die Height (mm) | 215 | 210 | 205 | 245 | 240 | 235 | 255 | 250 | 245 | 360 | 345 |

| Slide Adjustment (mm) | 30 | 30 | 30 | 40 | 40 | 40 | 50 | 50 | 50 | 50 | 50 |

| Slide Area (mm) | 330×225 | 330×225 | 330×225 | 420×320 | 420×320 | 420×320 | 540×350 | 540×350 | 540×350 | 600×400 | 600×400 |

| Bolster Area (mm) | 600×330×80 | 600×330×80 | 600×330×80 | 720×450×90 | 720×450×90 | 720×450×90 | 900×525×100 | 900×525×100 | 900×525×100 | 1000×590×120 | 1000×590×120 |

| Bed Opening (mm) | 400×300×100 | 400×300×100 | 400×300×100 | 500×400×100 | 500×400×100 | 500×400×100 | 600×525×100 | 600×525×100 | 600×525×100 | 480×120 | 480×120 |

| Motor Power (kW) | 3.7 | 3.7 | 3.7 | 5.5 | 5.5 | 5.5 | 11 | 11 | 11 | 15 | 15 |

| Size (mm) | 2133×1206×1011 | 2133×1206×1011 | 2133×1206×1011 | 2345×1400×1222 | 2345×1400×1222 | 2345×1400×1222 | 2695×1700×1400 | 2695×1700×1400 | 2695×1700×1400 | 1350×1840×2760 | 1350×1840×2760 |

| Weight (kg) | 2800 | 2800 | 2800 | 5000 | 5000 | 5000 | 6500 | 6500 | 6500 | 7500 | 7500 |

| Specification | GS-30 | GS-45 | GS-65 | GS-80 |

|---|---|---|---|---|

| AA (Overall Height) | 1940 | 2165 | 2278 | 2490 |

| AB (Base Width) | 889 | 1100 | 1300 | 1350 |

| AC (Base Depth) | 822 | 1022 | 1170 | 1260 |

| AD (Column Center Height) | 1066 | 1246 | 1555 | 1720 |

| AE (Total Depth) | 1166 | 1400 | 1700 | 1840 |

| BA (Distance Between Columns) | 327.5 | 400 | 485 | 511 |

| BB (Bolster Width) | 600 | 720 | 900 | 1000 |

| BC (Bolster Length) | 330 | 454 | 520 | 590 |

| BD (Slide Width) | 152.5 | 210 | 245 | 320 |

| BE (Slide Length) | 292.5 | 350 | 385 | 420 |

| BF (Table Height from Floor) | 440 | 580 | 650 | 620 |

| HA (Machine Height incl. Motor) | 2122 | 2360 | 2549 | 2750 |

| HB (Motor Height Above Frame) | 775 | 815 | 820 | 865 |

| HC (Frame Clearance Height) | 890 | 1040 | 1115 | 1277 |

Be the first to review “Three-circular guide pillar high speed punch”

Like what you see?

Check our case studies.

Reviews

There are no reviews yet.