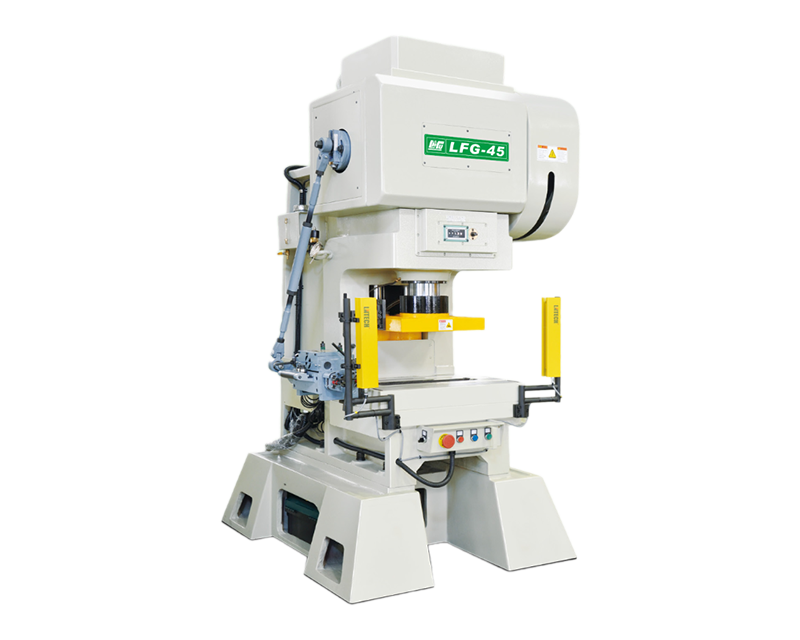

New H-frame double crank high speed press

Product Description

GP Series High-Capacity Straight Side Press Machines (85T–550T)

The GP Series Straight Side Mechanical Press is built for heavy-duty and high-precision metal stamping applications. With capacities ranging from 85 tons to 550 tons, this series is widely used in automotive chassis components, structural steel stamping, appliance housings, and high-volume progressive die operations.

Key Features

-

Wide Tonnage Range

Models from 85T to 550T provide flexibility for both mid-sized production and high-capacity industrial stamping. -

High-Speed Performance with Stability

Stroke speeds up to 500 SPM on smaller models and 260 SPM on the 550T model. All models feature 30 mm stroke length, ensuring uniform process control across the series. -

Adjustable Die Height and Slide Stroke

Slide adjustment of 50 mm with die height ranges up to 530 mm, supporting versatile die setups for various part geometries. -

Reinforced Bolster & Slide Plates

Extra-large bolster and slide tables (up to 3300 mm in length) allow secure mounting of large tooling, ideal for multi-stage or progressive dies. -

Optimized Frame Rigidity

Straight side frame minimizes deflection during heavy loading, enhancing part consistency and machine lifespan. -

Powerful Main Motors

Main motor power from 22 kW to 90 kW supports long production cycles and seamless integration with automated lines. -

Precise Linear Height Control

Linear height tolerance maintained within ±15 mm to ±30 mm, depending on the model, ensuring stamping precision at every stroke.

Application Scenarios

-

Chassis and body part stamping for automotive manufacturing

-

Structural part punching for appliances and HVAC

-

Medium to large-scale progressive die operations

-

Electrical cabinet frames and reinforcement stamping

-

Heavy-gauge component forming in steel and aluminum

Optional Add-ons

-

Servo feeder, decoiler, and transfer system integration

-

CE/UL-certified electrical cabinet and safety features

-

Touchscreen HMI with programmable stroke settings

-

Pneumatic or hydraulic die cushion system

-

Automatic die clamping and quick-change systems

OEM customization and engineering support are available. Contact us for technical drawings, quotation, or tailored solutions for your production line.

| Model | GP-85T | GP-125T | GP-160T | GP-220T | GP-300T | GP-350T | GP-400T (3-point) | GP-450T (3-point) | GP-550T (3-point) |

|---|---|---|---|---|---|---|---|---|---|

| Nominal Press Capacity (tons) | 85 | 125 | 160 | 220 | 300 | 350 | 400 | 450 | 550 |

| Capacity Occur Point (mm) | 2.0 | 3.2 | 3.2 | 3.2 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Stroke Length (mm) | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Strokes Per Minute (SPM) | 200–500 | 150–500 | 150–500 | 150–450 | 100–350 | 100–300 | 100–300 | 100–300 | 60–260 |

| Die Height (mm) | 330–380 | 360–410 | 360–410 | 370–420 | 400–450 | 400–450 | 450–500 | 450–500 | 480–530 |

| Slide Adjustment (mm) | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Bolster Plate (mm) | 1100×750 | 1400×850 | 1600×900 | 1900×1000 | 2300×1000 | 2500×1000 | 2800×1200 | 3000×1200 | 3300×1200 |

| Slide Plate (mm) | 1100×500 | 1400×600 | 1600×600 | 1900×700 | 2300×900 | 2500×900 | 2800×1000 | 3000×1000 | 3300×1100 |

| Bolster Hole (mm) | 800×150 | 1000×200 | 1100×200 | 1300×250 | 1800×300 | 2000×300 | 2500×450 | 2700×450 | 3000×450 |

| Linear Height (mm) | 175±15 | 195±15 | 200±30 | 200±30 | 210±30 | 220±30 | 230±30 | 270±30 | 270±30 |

| Main Motor Power (kW) | 22 | 37 | 37 | 45 | 55 | 55 | 75 | 75 | 90 |

| Outline Dimensions (mm) | 2530×1680×3935 | 3020×1800×4136 | 3300×1900×4250 | 3590×2100×4410 | 4060×2300×5105 | 4260×2300×5105 | 4640×2600×5405 | 4840×2600×5550 | 5300×2800×5650 |

Be the first to review “New H-frame double crank high speed press”

Like what you see?

Check our case studies.

Reviews

There are no reviews yet.