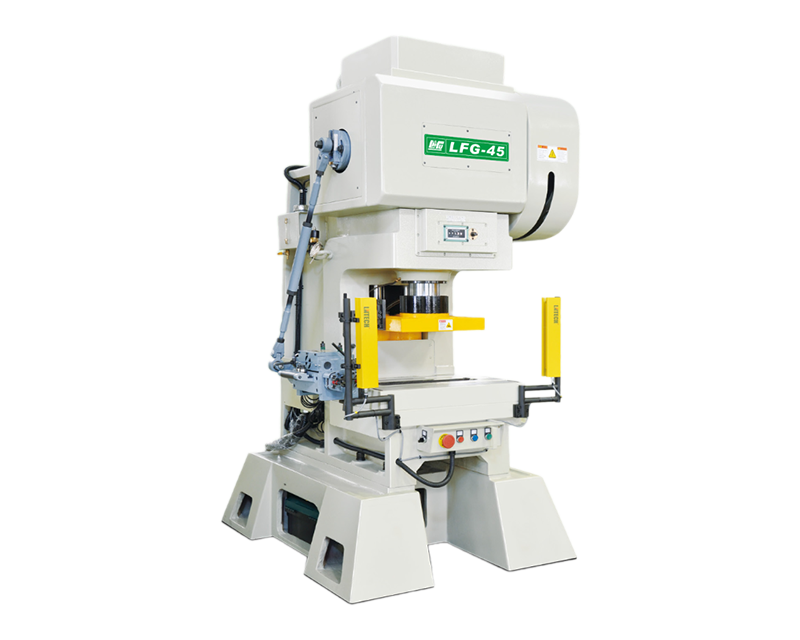

H-frame double crank high speed press

Product Description

GPH Series High-Speed Press Machines (45–300 Ton)

The GPH Series is a line of high-speed mechanical presses designed for precision metal stamping, particularly in electronics, automotive terminals, and hardware production. With a press capacity range of 45 to 300 tons, this series delivers exceptionally fast stroke speeds up to 700 SPM, making it ideal for progressive die stamping, connector production, motor cores, and small parts forming.

Combining compact footprint, adjustable feed line height, and GB/JIS-class precision, the GPH series ensures high repeatability, energy efficiency, and seamless integration with feeding automation systems.

Key Features

- Ultra-High Stroke Speed

Up to 700 strokes per minute on models up to 125T—ideal for micro-parts and progressive die runs. - Consistent Stroke Length: 30 mm

Short and efficient for thin material punching and precise blanking. - Compact & Stable Design

Heavy-duty frame paired with precision-machined slide and bolster plates. - Feed Line Friendly

Adjustable feed height from 135 to 210 mm, allows integration with servo feeders and NC straighteners. - Deep Bed Opening & Large Slide Area

Suitable for wide-strip feeding, multi-stage tools, and high-speed progressive lines. - Rated Tonnage at Shallow Points

Ensures effective force delivery at 1.6–3.2 mm, reducing wear on dies and improving forming quality.

Application Scenarios

- Terminal stamping (EV, electronics, telecom)

- SIM card and connector production

- Motor stator and rotor lamination punching

- Mobile phone hardware, precision bracket forming

- High-volume progressive stamping lines

Optional Features

- Servo or NC roll feeder

- Pneumatic clutch & brake system

- Lubrication system with temperature control

- Die monitoring and overload protection

- CE / UL electrical cabinet compliance

| Model | GPH-45T | GPH-65T | GPH-85T | GPH-125T | GPH-220T | GPH-300T |

|---|---|---|---|---|---|---|

| Rated Tonnage Point (mm) | 1.6 | 2.0 | 2.0 | 3.2 | 3.2 | 3.2 |

| Stroke Length (mm) | 30 | 30 | 30 | 30 | 30 | 30 |

| Number of Strokes (SPM) | 150–700 | 150–700 | 150–700 | 150–700 | 150–500 | 150–450 |

| Bolster Plate Size (mm) | 750×550 | 950×650 | 1100×750 | 1400×850 | 1800×950 | 2200×1000 |

| Bed Opening (mm) | 550×125 | 700×125 | 800×150 | 1000×200 | 1300×250 | 1800×300 |

| Slide Plate Size (mm) | 750×380 | 950×420 | 1100×500 | 1400×600 | 1800×700 | 2200×900 |

| Die Height (mm) | 240–290 | 300–350 | 330–380 | 360–410 | 370–420 | 400–450 |

| Modulation Motor (kW) | 0.4 | 0.4 | 0.75 | 0.75 | 1.5 | 1.5 |

| Feed Line Height (mm) | 135±15 | 160±15 | 175±15 | 195±15 | 200±15 | 210±15 |

| Main Motor (kW) | 15 | 19 | 22 | 37 | 45 | 55 |

| Total Weight (Tons) | 9.5 | 12.5 | 18 | 30 | 42 | 65 |

Be the first to review “H-frame double crank high speed press”

Like what you see?

Check our case studies.

Reviews

There are no reviews yet.